C-867.1U PILine® Motion Controller

For Single-Axis Positioning Stages with PILine® Ultrasonic Piezo Motor

- Integrated power amplifier with dynamic frequency control

- Multifunctional encoder input: A/B, sin/cos, BiSS

- Macro programmable for stand-alone functionality

- Integrated Interfaces: USB, RS-232, SPI, I/O, joystick

- Daisy chain networking

Servo controller and power amplifier

Single-axis benchtop device with special PID controller for PILine® ultrasonic piezo motors. Network capable with up to 16 units on a single interface. Power amplifier for PILine® ultrasonic piezo motors and positioners with performance class 1 and 2 piezo motors. Dynamic frequency control for optimum control.

Motion profiles

Point-to-point, trapezoidal velocity profile. User-definable trajectories (e.g., circles, sine curves) from externally fed points.

Interfaces and communication, encoder input

USB-, RS-232-, SPI interface for commanding. I/O lines for automation. Interface for analog joystick. Differentially transmitted A/B signals (TTL) or sin/cos signals (1 Vss). BiSS interface for absolute encoders. Inputs for TTL signals from limit and reference point switches.

Extensive functions, software support

Powerful macro command language. Nonvolatile macro storage, e.g., for stand-alone operation with autostart macro. Data recorder. ID chip detection for fast startup. PID controller, parameter changing during operation. Extensive software support, e.g., for NI LabVIEW, C, C++, MATLAB, Python. PIMikroMove user software.

Fields of application

- Micromanipulation

- Automation

- Biotechnology

- Sample manipulation

- Sample positioning

- Optical Metrology

Specifications

Specifications

Motion and control | C-867.1U |

|---|---|

Controller type | Programmable PID control, parameter changing during operation |

Motion profiles | Point-to-point trapeze, user-definable trajectories |

Encoder input | Sin/cos (differential), A/B (TTL, differential), BiSS interface |

Stall detection | Servo off, triggered by programmable position error or power level |

Limit switches | 2 programmable TTL lines per axis |

Reference point switch | 1 programmable TTL line per axis |

Interfaces and operation | C-867.1U |

|---|---|

Communication interfaces | USB, RS-232, SPI |

Motor connection | Sub-D 15 (f) |

Controller network | Up to 16 units on a single interface |

I/O lines | 4 analog / digital inputs 4 digital outputs to mini DIN, 9-pin Digital: TTL Analog: 0 to 5 V |

Command set | PI General Command Set (GCS) |

User software | PIMikroMove |

Application programming interfaces | API for C / C++ / C# / VB.NET / MATLAB / Python, drivers for NI LabVIEW |

Supported functions | Startup macro. Data recorder for recording operating data such as motor voltage, velocity, position or position error. ID chip detection. |

Manual control | Pushbutton box, analog joystick |

Downloads

Product Note

Product Change Notification C-819.JA, C-819.JAY

Datasheet

Documentation

User Manual C867T0026

SPI Interface of C-867 PILine® Controllers

User Manual MS223

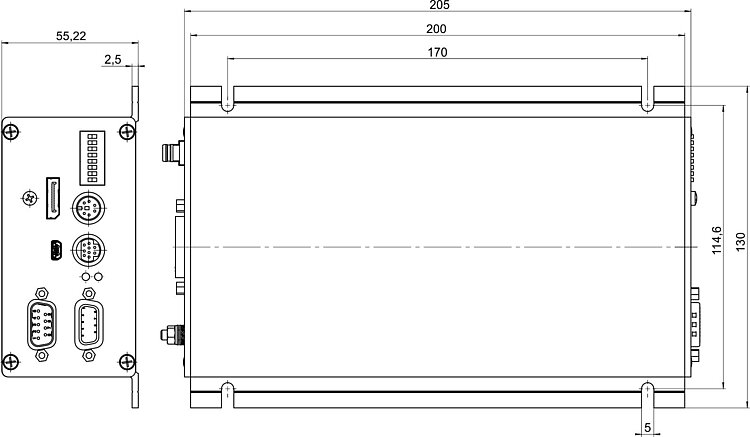

C-867.1U Piezomotor Controller / Driver, Networkable, 1 Channel, for PILine® Systems with Sub-D Connector(s)

3D Models

C-867.1U 3-D model

Software Files

PI Software Suite C-990.CD1

C-990.CD1 Releasenews

General Software Documentation

User Manual A000T0075

Implementing a C-887 PI Controller in TwinCAT 3.1

Software Manual SM157

PIPython - Programming PI Controllers with Python

User Manual A000T0067

Information on the PIStages3 database. What must be considered when changing from PIStages2 to PIStages3.

Software Manual SM156

PIStages3Editor for editing the PIStages3 database

Software Manual SM151

PI GCS DLL

Software Manual SM148

PIMikroMove

Software Manual SM155

PI MATLAB Driver GCS 2.0

User Manual A000T0028

Updating PI Software with PIUpdateFinder

Software Manual SM146

GCS Array Data Format

Software Manual SM158

PI GCS2 Driver Library for NI LabVIEW

Technical Note A000T0089

PI Software on ARM-Based Platforms

User Manual SM164

Updating controller firmware with PIFirmwareManager

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Accessories

Come Ricevere un’Offerta

Chiedi ad un Ingegnere!

Ricevere rapidamente una risposta alla tua risposta via email o telefono da un Sales Engineer dalla sede PI più vicina a te.