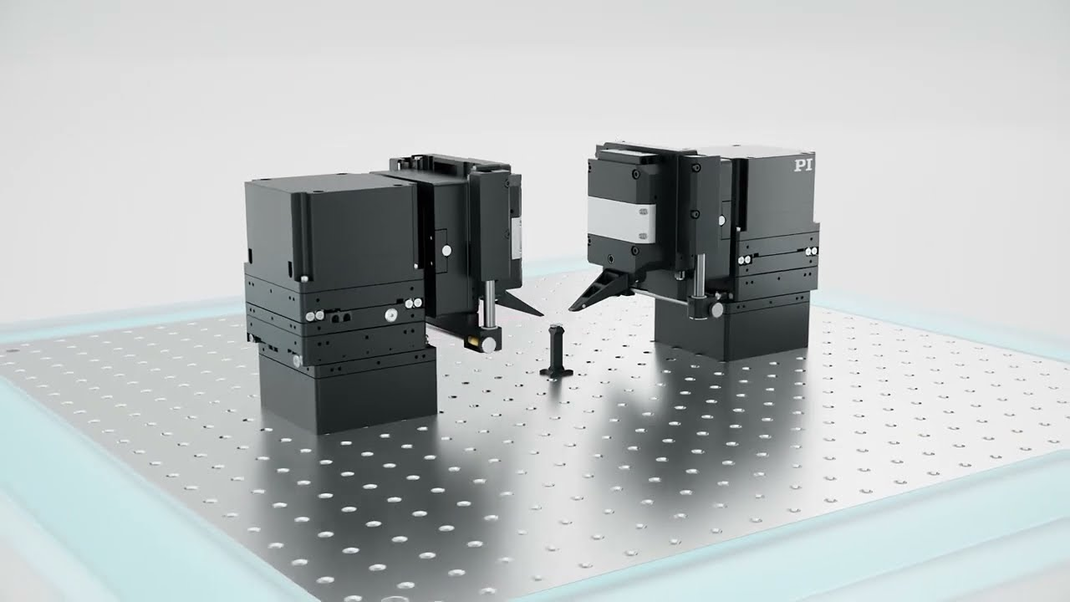

Testing and Probing for Mass Production

Cost-Optimized Fast Alignment Solutions for High-Volume Production of PICs

Silicon photonics is a cornerstone of breakthrough advances such as data processing, communications, artificial intelligence, and quantum computing. As global demand for silicon photonics integrated circuits surges, high-volume manufacturing has become vital to support this rapid growth. PI’s cutting-edge technologies offer unparalleled precision, speed, and reliability in probing and testing applications, ensuring production-ready performance at scale. Being purpose-engineered solutions with a focus on automation and throughput optimization, PI’s systems are tailored to meet the exacting requirements of modern silicon photonics integrated circuit fabrication. These advanced systems empower manufacturers to achieve unmatched efficiency, consistency, and excellence in their processes.

Key Features

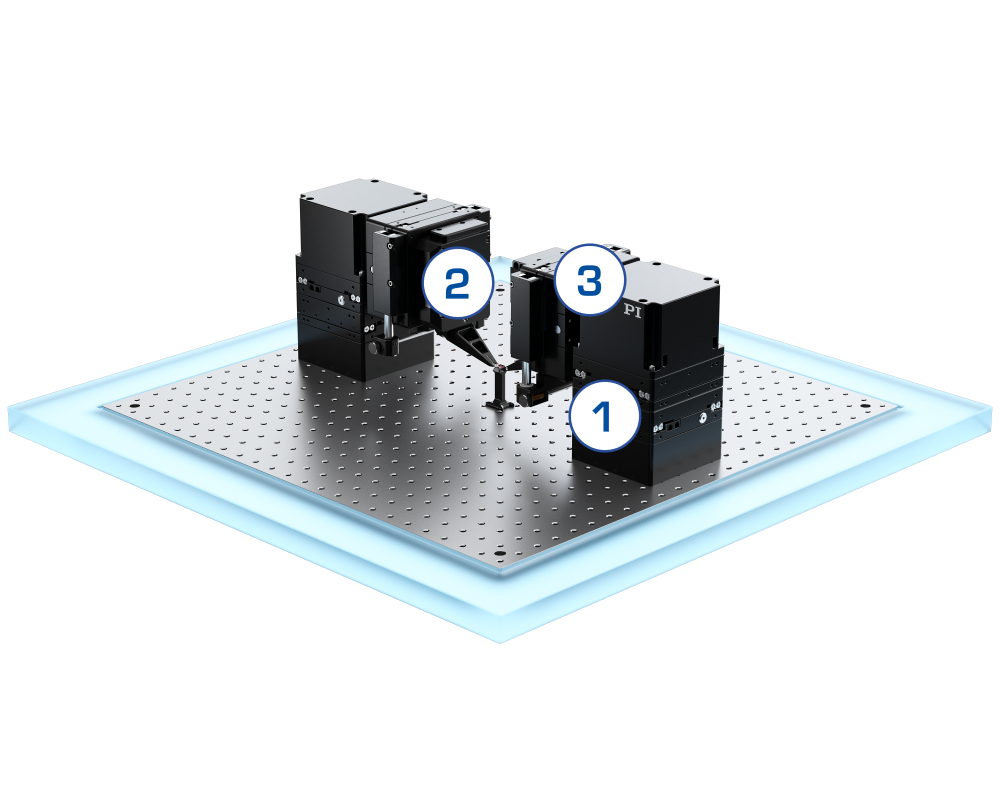

XYZ Axis - Fiber-to-Fiber and Fiber-to-Waveguide Alignments

- Compact integrated XYZ version featuring direct drive motor technology for high dynamics and fast step-and-settle

- Compact geometry using ultra-precision crossed roller bearings with minimized angular amplified errors for highly repeatable positioning at the probe tip

- Adjustable magnetic counterbalance enabling vertical operation with minimal impact on form factor

- High-resolution incremental linear encoders with low CTE scales for repeatable and accurate positioning

>> Direct Drive Linear Motor Stages

θZ Axis - Precise Rotational Positioning of Photonic Devices

- Innovative flexure design featuring direct drive motor technology

- Purpose-engineered for highly dynamic, short-stroke, repetitive motion sequences used in advanced photonics alignment

- Optimized moving platform for convenient mounting with minimal lever arm for direct optical probing

- High-resolution incremental linear encoder with low CTE scales

θY and θZ Axis - Fine Angular Fiber Positioning During Setup

- Ultra-fine automated angular adjustments (ΘY and θZ) for extended travel of ±4° with microradian precision

- Stepper motor technology for the highest stiffness on pitch and yaw axes while XYZ movement and rotation around the optical axis are highly dynamic

- Easy access to the PIC or wafer with reduced applied moment load

- Innovative design with improved resonant characteristics, enhancing system stability and first-mode resonance performance

Motion Control

- Flexible expandable controller platform

- IP-protected onboard algorithms with easy functioning

- Advanced EtherCAT control system with optimized master processor providing rapid signal analysis for onboard machine learning

- Fast, synchronous data processing of multi-axis position and analog voltage signals

- Real-time execution and algorithmic computation

- Ultra-low noise drives with high-resolution analog inputs (24 bits)

>> A-81x PIglide Motion Controller

Do you have questions about our solutions? Our specialists are happy to help you!

Contattaci oggi stesso!